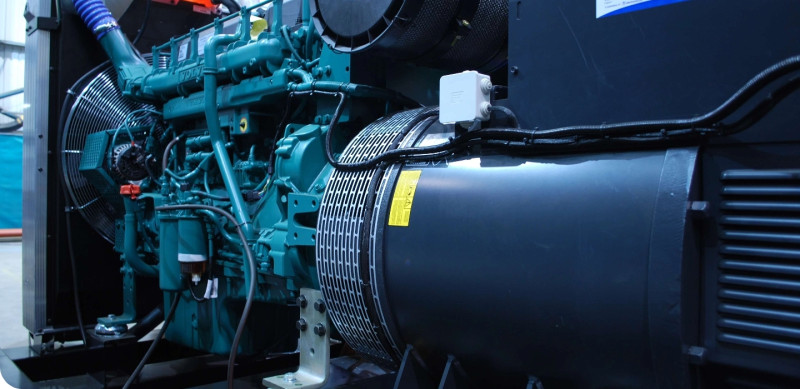

Our Open Set Generators deliver reliable backup power from 20–3,000 kVA, designed for seamless integration into plant rooms and controlled environments. Built without an outer enclosure, these units offer improved airflow and easy access for servicing. Each Generator includes an integral control panel and outgoing circuit breaker as standard, supporting safe and efficient operation indoors.

Open Set Generator installations come with their own challenges, from restricted access routes to complex room layouts. Our in-house engineers and project managers design around your space, ensuring smooth delivery, precise fit, and optimal performance. Units are built on robust steel base frames, with or without integral fuel tanks depending on the application, allowing flexibility in system design and integration.

Open Set Generator installations come with their own challenges, from restricted access routes to complex room layouts. Our in-house engineers and project managers design around your space, ensuring smooth delivery, precise fit, and optimal performance.

Get in touch to discuss your Open Set Generator project. Our team is ready to design a solution that meets your site, standards, and schedule.

There are many benefits of getting your generator serviced on an annual basis, and these include:

Ensuring your generator works when you need it the most: The last thing you need is to find out your generator doesn’t work when there is a power outage. Regular generator maintenance will ensure you know your generator is working and will serve you well if/when the power decides to stop working.

Lessens fuel problems: Fuel problems can be a real problem if left untreated. Over time, algae can build up in the fuel system, fuel injectors can become clogged and batteries can die. With regular maintenance you can help to avoid such problems and stop them from permanently damaging your generator.

Saves you money in the long run: If your generator stopped working without your realisation and the electricity was to go down too, your potential losses could be costly. Not only would you lose money as a business, you may even have to spend money replacing your generator.

Will keep your critical power equipment running for longer: Generators that aren’t serviced regularly tend to have shorter life spans than ones which are. Generator maintenance can determine any equipment issues and predict when end of life replacements will be needed.

Generator efficiency: With generator maintenance, all parts will be checked and tested and the system will be cleaned from potentially damaging dirt, debris or algae. This will make your diesel generator, natural gas generator or LPG generator far more efficient, and could end up saving you money in the long run too.

Ultimately, without generator maintenance, your business, site or facility could suffer losses that may be difficult to come back from.

Generators can be put into containers. There are a number of benefits to doing this including:

Easier transportation and installation making them ideal for temporary or remote applications.

They are more secure as typically they are lockable which prevents unauthorised access.

Containerised generators are protected from the weather

Noise is reduced as they can be fitted with soundproofing materials

Put simply, yes. A generator service and/or UPS service can determine any existing and future power supply problems that could impact equipment performance. Planned and preventative maintenance can extend machine efficiency, assures optimal working conditions and conserves the life span of the equipment. Along with determining when replacements will be needed for a seamless transition, planned and preventative maintenance is a far cheaper solution compared to complete equipment replacement.

When a power outage occurs, a UPS will immediately switch to battery power to provide a continuous power supply to connected equipment. However, the UPS batteries have a limited runtime, so a generator is needed to provide long-term power protection. When initiated the UPS will send a signal to the generator to start up. Once the generator is running, the UPS will switch to generator power. When the power outage is over and grid power is restored, the UPS will return to utility power and recharge its batteries. The generator will then shut down.

Electrical generators are pieces of critical power equipment that provide electricity when power from the power grid is unavailable. Interestingly enough, generators don’t actually create electricity. Instead, generators convert mechanical or chemical energy into electrical energy – by capturing the power of motion and turning it into electrical energy by forcing electrons from the external source through an electrical circuit. Once an electrical current has been established, it is directed through copper wires to power external machines, devices, or entire electrical systems.

Sizing your generator correctly is important to ensure you can power your equipment. To size an industrial generator you should consider the following factors:

What equipment the generator will be powering?: make list of the items that need to be powered and determine the starting and running wattage for each.

What is the total load requirement?: add up the starting and running wattage for all the equipment

What is the total load factor?: the load factor is the ratio of the average load to the peak load

What is the surge capacity?: The surge capacity is the amount of extra power that the generator can provide for a short period of time to equipment. It is typically 10-25% of the rated capacity of the generator.

Nearly all electronic and electrical equipment, regardless of how well-designed and built it is, will eventually break down unless it is maintained according to the manufacturer’s instructions. Wear and tear is common with electrical equipment, but it has severe consequences for UPS systems and generators, where financial, reputation and potentially life-threatening damage comes into play. It is highly recommended that as a minimum you service your power systems annually in order to maintain its working lifecycle. Our service contracts include everything from AC maintenance, DC maintenance and generator maintenance through to analogue metering, intelligent monitoring, remote monitoring and spare parts, as well as callouts, minor fault fixes and access to our customer portal, where you can access management information reports and other key details on your power supply systems.

Without proper maintenance, generators can fall prey to failures and power outages. Generator manufacturers generally recommend that a generator should be serviced after the first year of installation and on an annual basis there on after. We also suggest carrying out regular visual inspections to keep on top of any faults within your generator that may require maintenance sooner than anticipated.

Factors that may result in more frequent maintenance include:

Exposure to extreme temperatures and weather can damage components of the generator.

Airborne contaminants such as dust and sand may infiltrate the generator, causing damage to its internal components.

Excess usage: Most diesel generators are designed to provide backup power. Should a standby generator be used for prime power, care should be taken to ensure the generator is inspected frequently and only used for as long as it is required.

Lack of usage: Similarly, if a generator is left dormant longer than expected, engine exercise should be carried out to avoid battery failure.

To comply with British Standards, the base material should be either:

Concrete at least 100mm thick.

Paving stones at least 50mm thick.

Stonework at least 50mm thick.

The overall size of the base should be larger than the oil storage tank and any integral oil storage tank bund, so that when the oil storage tank is installed, the base has a clear projection of a minimum of 300mm around all sides of the oil storage tank.

We have no doubt of your trained eye, but an OFTEC inspection provides assurance that your tank is fine, and can function properly. When exposed to the elements, steel pipes can rust, and plastic becomes brittle. Similarly, poor installation can put large amounts of pressure on the tank, leading to leaks and pollution. Having your oil tanks inspected will considerably reduce any risk, and leave you less liable should an issue occur.

As batteries go unused, with no charging schedule, their battery life will decrease. When it comes to the self-discharge characteristics of lead-acid batteries for example, it is important that they are charged after 6-10 months of battery storage. Otherwise, permanent loss of capacity will occur between 18-30 months.

A petrol generator is an alternative to diesel but typically used only for short periods. Greener alternatives include natural gas. These generators rely on underground access to natural gas. Another option is propane which is generally chosen when natural gas isn’t available.

Diesel generators are those that are run on diesel, and can typically be divided into two basic parts: a diesel engine and an electrical generator. Diesel generators can be used to provide power to places that are not powered by a power grid or can be used as a backup in case of a power outage.

Natural gas generators use natural gas however, and are used in both emergency and portable generator types. They are one of the most affordable and effective fuels among non-renewable resources for power generation.

LPG (Liquid Petroleum Gas) generators have powerful engines that run smoothly and quietly while providing dependable power when you need it most.

A generator provides standby power until the mains power can be reinstated during a power outage. This is supported by a UPS (Uninterruptible Power Supply) which ensures a seamless transition from your mains power to your backup power supply. Batteries provide power to your UPS and generator.

Severe actions can be taken against companies that have not complied to regulations including fines, associated costs of production loss and cleaning and imprisonment. These are based on several factors concerning the overall damage of the spill, number of litres spilt and the duration it took place and of course the direct and indirect impact on the environment. Records have seen fines reach in the region of c£8M in recent years.