Dale’s industrial UPS systems are designed specifically for use in high-intensity, high-impact industrial environments. UPS is important in environments where loss of power can impact the safety of people, or cause severe damage to structures and buildings, making them unsafe. Dale offers both AC and DC industrial UPS units to suit your needs.

Industrial UPS power supply systems are designed to function well in temperatures anywhere from 15-55 degrees Celsius, in humidity levels of 10-95% and in areas with a lot of dust and contaminants in the air, some of which may be corrosive. They also last considerably longer than commercial systems, with an average design life of 20+ years, and offer battery support from 60 to 480 minutes (1 to 8 hours), so can survive more significant power outages without any interruption to infrastructure. Adverse conditions like these can naturally reduce the lifespan of the separate parts in a standard UPS, as well as the device, which is why it is so important for organisations whose power infrastructure will be battling the elements to have an industrial or environmental UPS power supply.

Put simply, yes. A generator service and/or UPS service can determine any existing and future power supply problems that could impact equipment performance. Planned and preventative maintenance can extend machine efficiency, assures optimal working conditions and conserves the life span of the equipment. Along with determining when replacements will be needed for a seamless transition, planned and preventative maintenance is a far cheaper solution compared to complete equipment replacement.

When disruption to your power occurs it will provide instantaneous protection by immediately resorting to the onboard battery which forms part of the uninterruptible power supply.

Nearly all electronic and electrical equipment, regardless of how well-designed and built it is, will eventually break down unless it is maintained according to the manufacturer’s instructions. Wear and tear is common with electrical equipment, but it has severe consequences for UPS systems and generators, where financial, reputation and potentially life-threatening damage comes into play. It is highly recommended that as a minimum you service your power systems annually in order to maintain its working lifecycle. Our service contracts include everything from AC maintenance, DC maintenance and generator maintenance through to analogue metering, intelligent monitoring, remote monitoring and spare parts, as well as callouts, minor fault fixes and access to our customer portal, where you can access management information reports and other key details on your power supply systems.

UPS manufacturers usually recommend that UPS maintenance should be carried out within the first year of installation, and then annually from there on out as a minimum. However, if you notice any issues with your UPS system beforehand, then you should always contact your power supply partner as soon as possible to rectify them, and to ensure that UPS repairs are carried out swiftly and efficiently. The right check up could be the difference between business continuity and costly downtime, so UPS maintenance is always worth the time and effort.

Batteries have a typical lifespan of 3 – 5 years, with causes of battery failure including loss of electrolyte and inaccurate float charge voltage. However, factors such as battery chemistry, battery cycling and suitable storage conditions can greatly affect how long your battery lasts. We strongly recommend carrying out battery maintenance tests to keep abreast of any battery faults or issues, as batteries are one of the most integral parts of your UPS system. Battery testers can visit your business, site or facility every 6 months to a year, ensuring you’re always in control of your critical power equipment.

As batteries go unused, with no charging schedule, their battery life will decrease. When it comes to the self-discharge characteristics of lead-acid batteries for example, it is important that they are charged after 6-10 months of battery storage. Otherwise, permanent loss of capacity will occur between 18-30 months.

Upon installation, the UPS requires further attention before it is fully operational. Certain connections, components and peripherals need to be checked and tested to ensure that the UPS works as designed. Once these checks have been completed, the UPS can then be commissioned and will operate at optimum performance without the need for more tests.

UPS maintenance is extensive and far-reaching, and when carried out by our technical team, is highly successful. UPS maintenance involves the testing and inspection of your UPS systems, and making any necessary adjustments for power continuity. A visual inspection of the area surrounding your UPS and battery equipment will typically be carried out first, with UPS maintenance seeking to identify any operational abnormalities. Following this, we can carry out battery maintenance, battery management, enclosure maintenance and load bank testing, as well as control system management, voltage testing, and replace faulty parts with new ones. This can include batteries, capacitors, alternators and fans.

An uninterruptible power supply (UPS) provides a source of power for the equipment it protects. If there is a disruption to power, the UPS has an on-board battery to automatically supply to electrical equipment until the disruption is over or back-up generators kick-in.

The UK electricity system has experienced high levels of grid resilience historically – offering a high degree of confidence to businesses and consumers that power will be available 24 hours a day, 7 days a week, 365 days per year. However, we must be able to respond to the more severe, less frequent events to ensure power supplies are maintained or restored quickly following such an event. Therefore, grid resilience is ‘the ability to withstand and reduce the magnitude and/or duration of disruptive events, which includes the capability to anticipate, absorb, adapt to, and/or rapidly recover from such events‘.

Remote monitoring systems allow you to check up on your UPS and generator systems from a computer or smart device from a remote location. Your device connects to offer reports and data on the functionality of your UPS and generator systems. Featured functions include checking vital systems, turning generators in the field on and off and viewing various statistics.

The standard lifespan for VRLA batteries is 3 – 5 years. However, expected battery life can vary dependent on environmental conditions, number of discharge cycles, and suitable maintenance. Having a regular schedule of battery maintenance and battery monitoring to ensure that you know when your batteries are reaching their end-of-life is always a good idea.

Hot-swappable batteries can be changed out while the UPS power supply system is running. User-replaceable batteries are typically found in smaller UPS systems and require no training nor tools to replace. Batteries can be both hot-swappable and user-replaceable.

The IEE defines ‘end of useful life’ for a UPS battery as the point where it can no longer supply 80% of its rated capacity in ampere-hours. When your battery reaches 80% of its rated capacity, the ageing process accelerates and the battery should be replaced.

Site assessment – Detailed site assessments are carried out to determine how your equipment can be delivered and installed on site. In the instance where sites involve additional requirements depending on the location, we can arrange anything that you need.

Delivery – We arrange the safe transport and delivery of your equipment to any site around the world at a time that suits the customer.

Installation – We manage every aspect of the installation to ensure that your equipment is efficiently and fully operational to your requirements.

System testing – Once installed, your equipment is thoroughly tested and commissioned to the customer’s specification ready for hand over.

End user training – We can train you to operate your equipment safely, so that you can make configuration changes when you want.

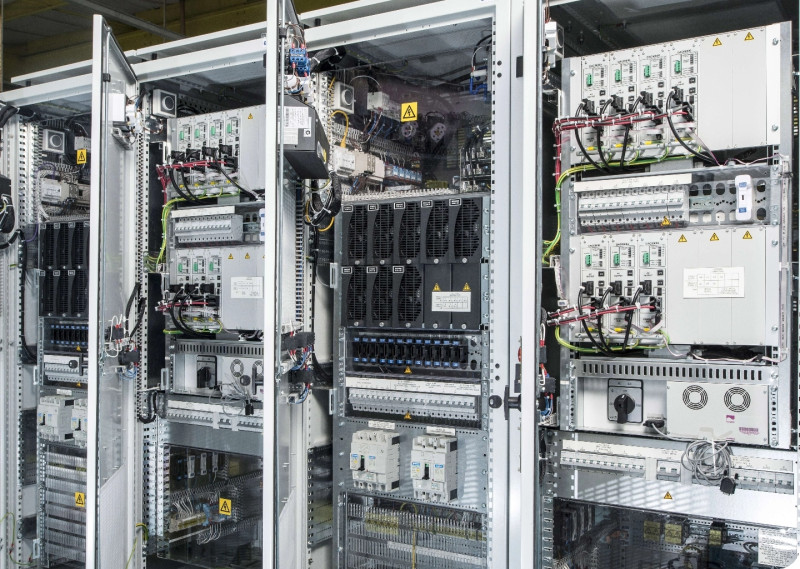

Our industrial UPS systems can be adapted and designed around your own space and infrastructure needs. Standard commercial UPS power supply systems come with several different options to ensure optimum performance for your application, while an industrial UPS can be customised entirely to your specifications and infrastructure needs, including containerised solutions. This will come with in-depth design documentation, and often in these applications, you can find that each component will have quality documentation of its own.